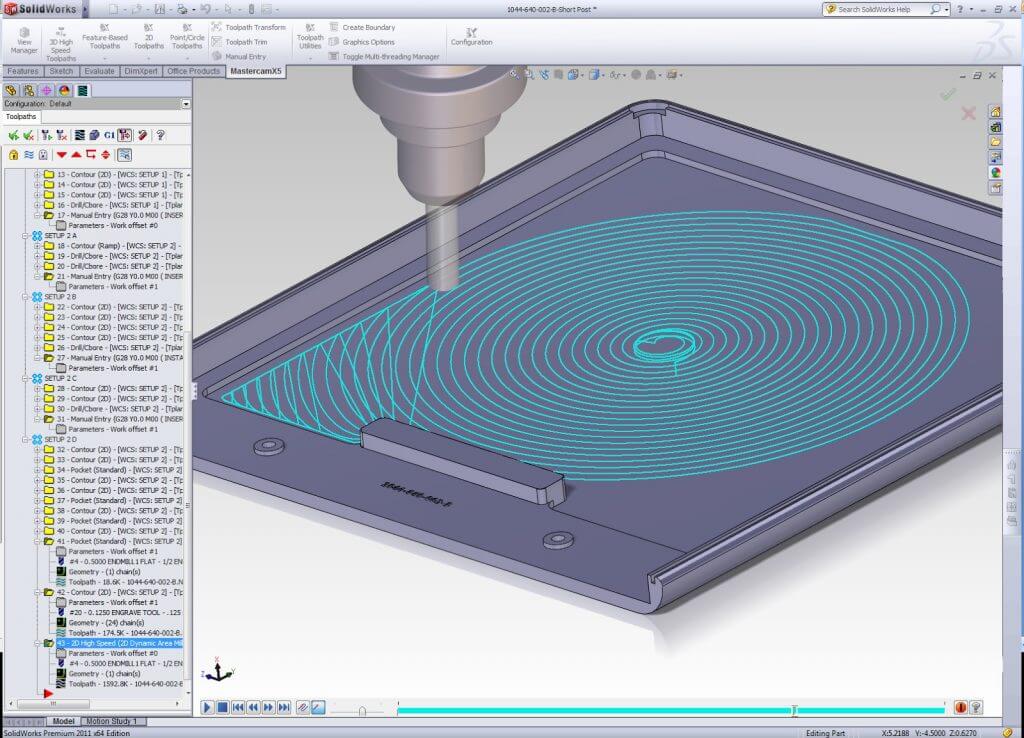

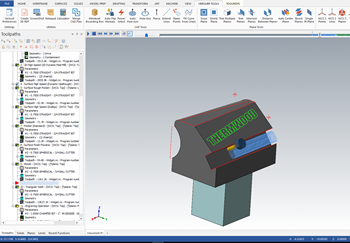

Students also learn to write CNC code without Geometric Dimensioning and Tolerancing (GD&T)ĬNC programming, setup, and machining require diverse skill sets.CNC PROGRAMMING & SET-UP WITH MASTERCAM.CNC PROGRAMMING FOR THE CNC MILL USING G AND M CODES.CNC LATHE AND MILL SET-UP APPLICATION LAB.CMM APPLICATION IN PC-DMIS® SOFTWARE – LEVEL 2.CMM APPLICATION IN PC-DMIS® SOFTWARE – LEVEL 1.CAD/CAM ADVANCED SHOP APPLICATIONS – PROJECT BASED.TEAM DEVELOPMENT FOR LEADERS & INFLUENCERS.Leadership for New and Future Supervisors.SOLIDWORKS MECHANICAL DESIGN (Beginner – Intermediate).MasterCAM for Milling and Turning Center Application.Time Management and Effective Communication Skills.

Internal Quality Management Systems Auditor Training (AS9100 Rev.Effective Communication Skills for Professionals.Coaching Skills for New and Future Managers.MICROSOFT® EXCEL (INTERMEDIATE-ADVANCED).

MICROSOFT® OFFICE ESSENTIALS FOR SMALL COMPANIES.Team Building and Working Collaboratively.APICS ESSENTIAL SKILLS FOR INVENTORY CONTROL.APICS ESSENTIALS OF OPERATIONS & SUPPLY CHAIN MANAGEMENT.APICS ESSENTIAL SKILLS FOR WAREHOUSE & DISTRIBUTION EMPLOYEES.

0 kommentar(er)

0 kommentar(er)